- Mobile:

- +86 13625872111

- Tel:

- 0577-59886565

- Email:

- admin@bcmachinery.cn

- Add:

- #358 Weier Road Nanbin Street Ruian City Zhejiang China

Sample Show

Brief Description

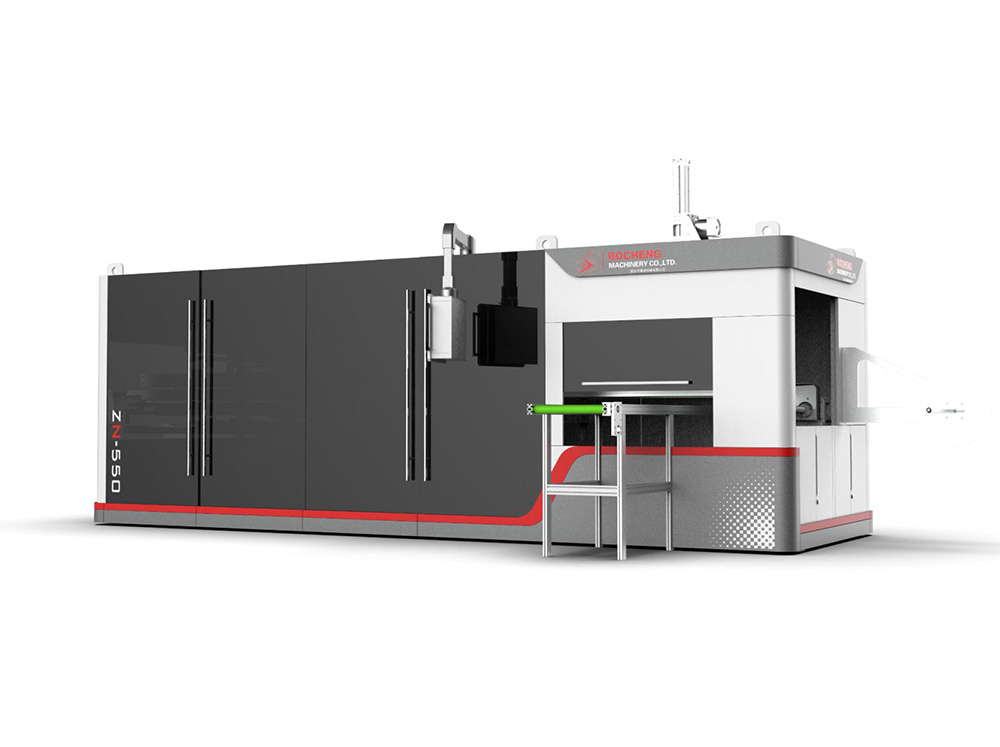

BC-HEPB is our best selling Automatic Heat Sealing Paper Box Molding Machine

With advanced design and intelligent program, more reliable and durable, cost effective.

Original design, New paper box with plastic lid molding process-- Automatic heat sealing paper box with plastic lid machine.

Product Molding Theory:Suitable to forming white cardboard, brown paper and so on,There are two sides of paper, One side of paper is filmed, another side is coated,The heating mold melt the PE film, meanwhile the box molding completely,The advantage between glue forming machine is not only beautiful but also practical, As a food container, it’s more ECO-Friendly and healthy.

Advanced & Advantage

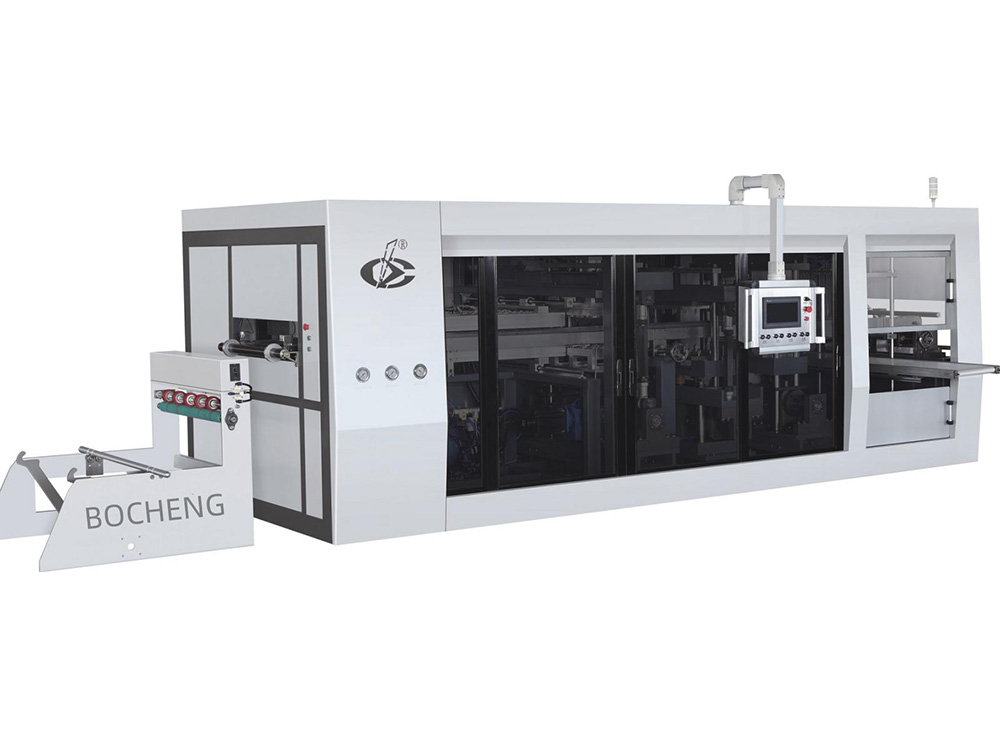

* Mechanical transmission、High speed、Energy saving、Stable Performance、Easy operation、microcomputer monitor、advanced and technological product.

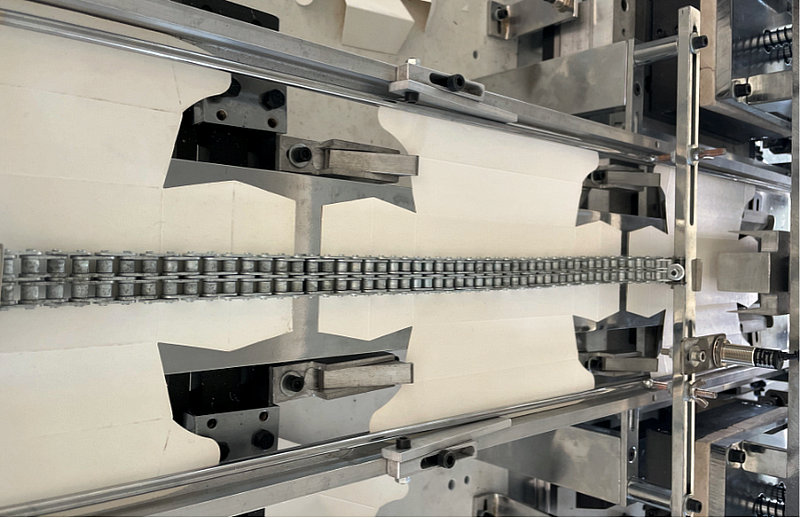

* Paper conveying operated by mechanical structure, Automatic feeding paper and conveying paper, Stable and efficient, Original design with two working stations automatic corner folding and mold heating forming, Product use aluminum alloy good quality mold, the advantage including weightless mold with high accuracy and long life, perfect adhesion with seamless looking, products are beautiful and practical, Compare with glue molding machine the molding is higher level, it is the ideal equipment for the production of folding paper box.

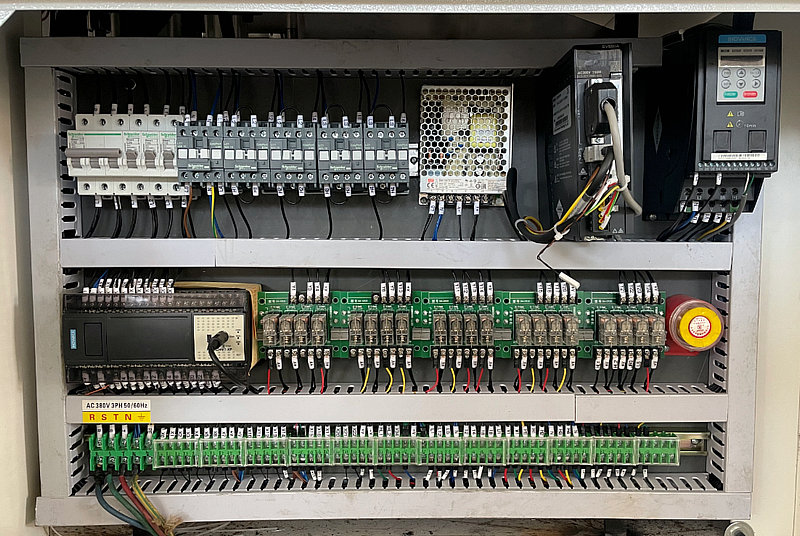

* Equipment controlled by microcomputer, Machine procedure of paper sucking, paper conveying, corner folding, forming and collecting are controlled by PLC. Electrical part and other key components are using well-known international brands. Ensure quality, Easy to operate, Full intelligent operation, Save labor costs, One person can operate several machines, it is a efficient and practical intelligent products.

* Mechanical transmission, good quality main motor

* PLC Program control, easy operate, and intelligent

* Quality mold, Using Aviation aluminium alloy material, high precision, light weight, Energy saving

* Quality electric elements, long life, (WVT, Schneider, AUTONICS, AirTAC famous brand)

* Working power only 5KW, save cost (not include the air compressor power)

* Stable Speed 25 times per minute. It has the monitor computer system .If the fault the machine will stop and alarming

* Equipment using optical monitoring, the whole machine with multiple monitoring devices, paper sending, paper passing, paper holder , molding can be real-time display on the operating screen, photoelectric monitoring location go wrong, the machine will automatically stop.

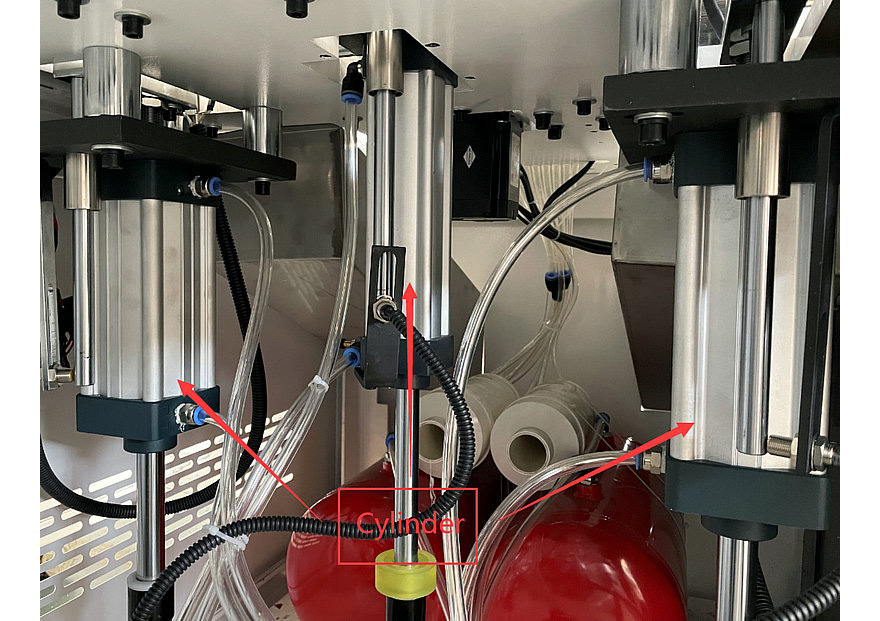

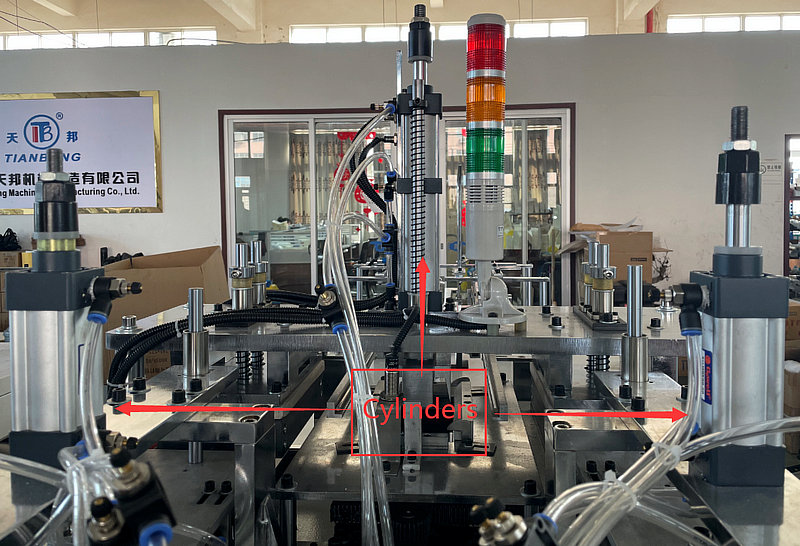

* The machine equipped with two sets of molds are all made of aluminum alloy,Through computer milling and wire cutting,To ensure the accuracy of the mold,Improve product molding quality,At the same time to extend mold life,Equipped with imported Parker rodless cylinder,make sure the Smooth and accurate mechanical action.

* Installed molds equipped with excellent thermal conductivity of heating pipes and heating rods, molds heated evenly, the product have beautiful outward, and easy to maintain.

Quality Electronic

|

|

| |||||

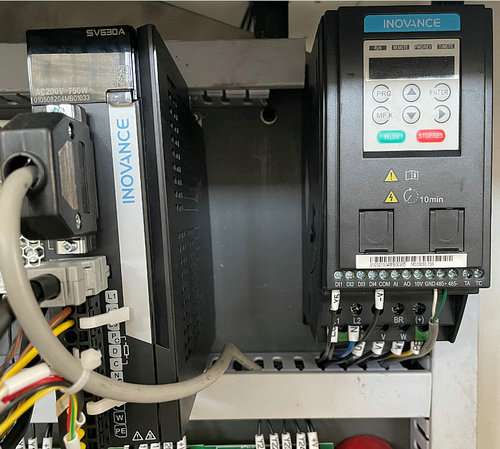

PLC | Paper stock frame | Transducer | |||||

| |||||||

|

|

| |||||

Transmission motor | Mechanical transmission | Frequency converter | |||||

| |||||||

|

|

|

|

| |||

Sensor 1 | Sensor 2 | Sensor 4 | Sensor 5 | ||||

Monitor the paper quantity level | Monitor mold in both working stations | Monitor paper conveying in both sides | Monitor box collection,in both working stations | ||||

| |||||||

|

| ||||||

Under part Cylinders | Up part Cylinders | ||||||

|

| ||||||

|

|

| |||||

Heating mold in both working stations | Paper conveying path | Main cylinder | |||||

2, A Heater (up mold) | 3, A Heater (down mold) | 4, B Heater (up mold) | 5, B Heater (up mold) |

6, A Heater switch | 7, A Heater switch | 8, B Heater switch | 9, B Heater switch |

| 1,Touch screen | 10, Power switch | 11, Start switch | 12, Stop switch | 13, Urgent stop |

Operate the machine | Turn on the machine | Start the machine | Stop the machine |

|

CIRCUIT BOARD

Technical Specification

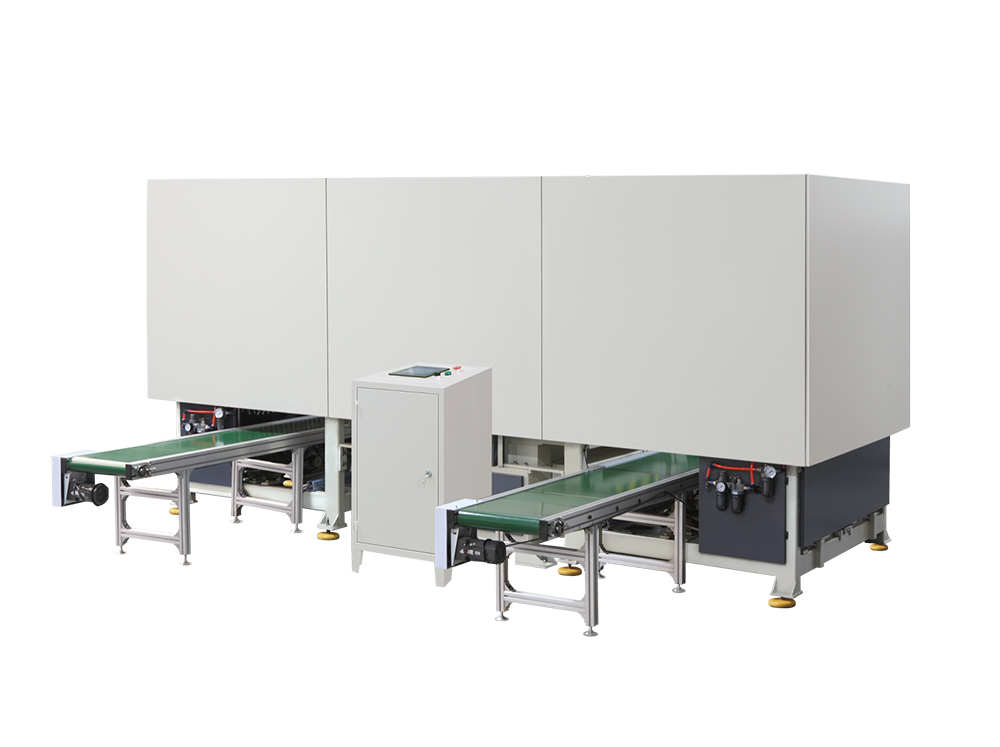

| Type | BC-HEPB |

Production capacity | 20-30 times/min (The actual output is subject to the size of the product) |

Maximum size: | 300 x 270mm |

Max Paper Convey Width: | 270mm |

Suitable Material: | 200-400g/m2 (one side or two side PE Coated paper) |

Total Power: | 3KW |

Total Weight: | 1T |

Overall Dimension: | 2200 x 1250 x 1730 mm |

Working Air Source: | Air pressure 0.5Mpa (Need to buy compressor) |

Gross weight | 800 KG (Wooden box packing weight) |

Grouped equipment | Need to buy air compressor |

Working volume | 0.3-0.4 m³/min |

Components Brand

Motor | Main motor | WVT (CHINA) |

Electrical equipment | PLC | INOVANCE(CHINA) |

Frequency converter | INOVANCE(CHINA) | |

Contactor | SCHNEIDER | |

Breaker | SCHNEIDER | |

Start switch | AUTONICS (KOREA) | |

Photoelectric switch | AUTONICS (KOREA) | |

Temperature control | YATAI(CHINA) | |

Pneumatic | Main cylinder | AirTAC (TAIWAN) |

Other pneumatic components | FAMOUS BRAND (CHINA) | |

other bearings | HBR (CHINA) |

Quotation

NO. | DESCRIPTION | QUANTITY | FOB NINGBO PRICE | |

1 | BC-HEPB Automatic Heat Sealing Paper Box Molding Machine (Include one set of mold) | 1(set) | ¥106,000 RMB | |

2 | Extra mold | 1(set) | ¥6,000 RMB | |

Payment term | 30% deposit, 70% before shipment | |||

Port | FOB Ningbo or Shanghai port | |||

Delivery time | 20 working days in general, 40 working days for customized machine | |||

Other | Buyer bears the cost during the installation & training (buyer should pay engineer's round way air ticket , food room and pay 100USD per day as daily expense) | |||

Container loading | 20 Feet container load 4sets BC-HEPB | |||

After Sales Service

| 1 | Warranty: We offer 12 months warranty. During the warranty period, we provide free |

2 | Spare Parts: Each machine has its standard spare parts. |

3 | Manual, Video, to help operate machine, Questions response within 48 hours (except holiday). |

4 | FREE: The buyer come to learn how to operate machine, how to adjust, how to change parts. It is free. |

5 | The seller agrees to dispatch technician for installation & training, the cost covered by the buyer. |

6 | Mechanic overseas Cost include: |

P. S. If different width, we can do it according to your requirement.

Next:没有了!