- Mobile:

- +86 13625872111

- Tel:

- 0577-59886565

- Email:

- admin@bcmachinery.cn

- Add:

- #358 Weier Road Nanbin Street Ruian City Zhejiang China

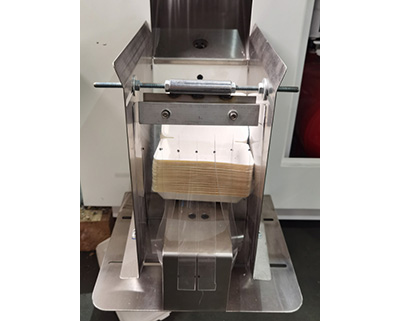

Sample Show

Brief Description

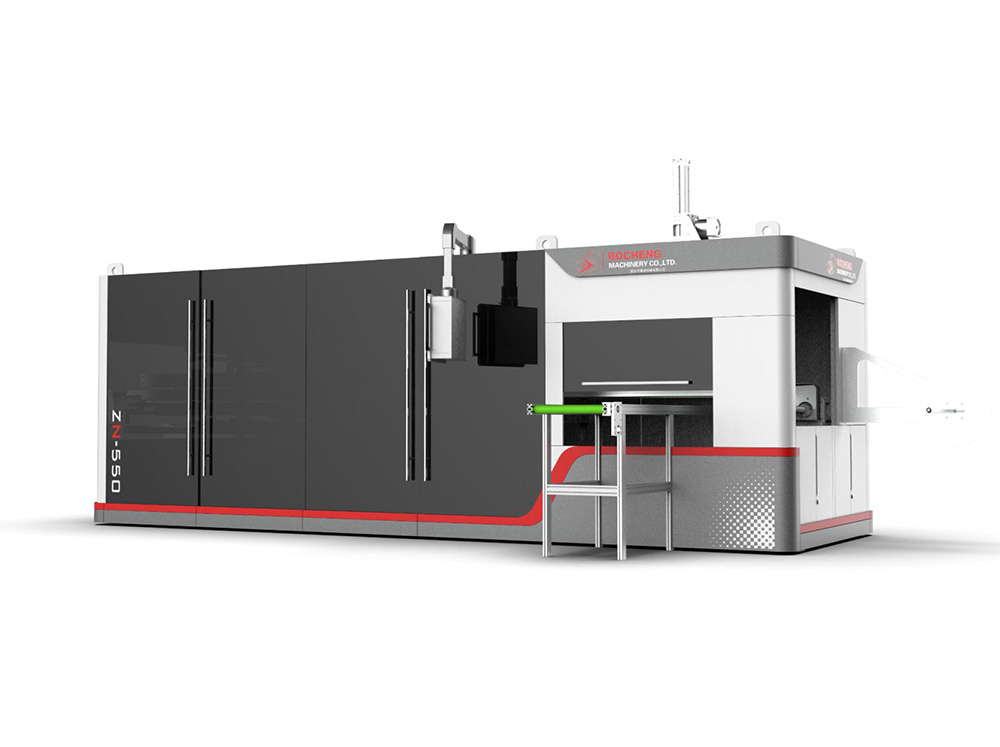

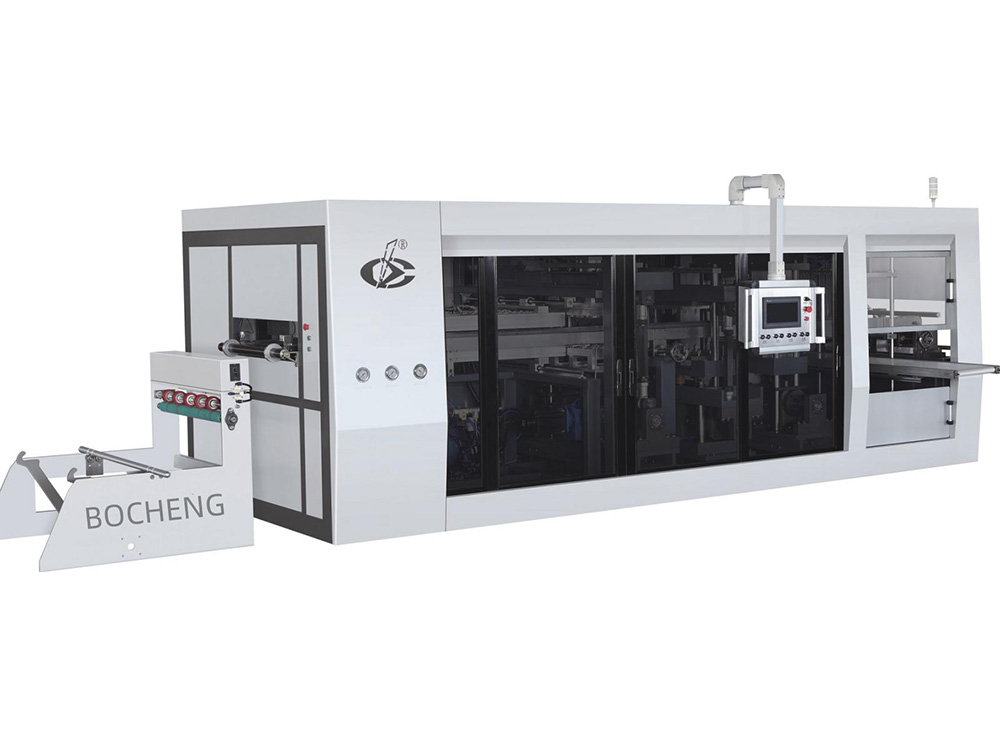

BC-700 is our best selling Automatic meal box making machine.

With advanced design and intelligent program, more reliable and durable, cost effective.

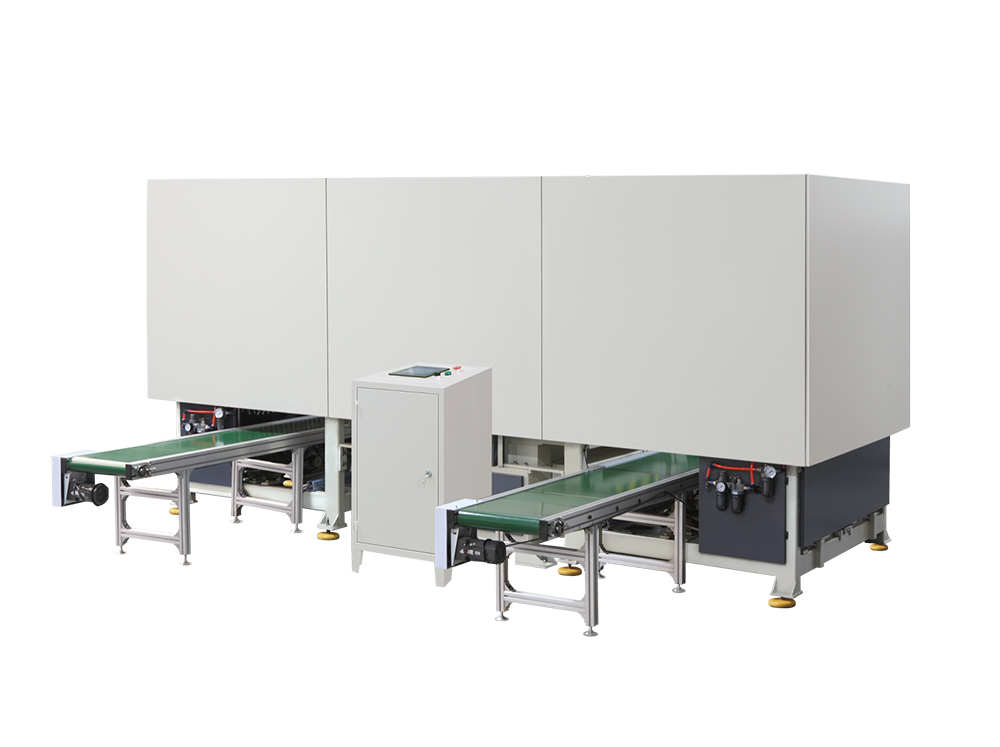

It makes one-side PE-film-coated paper meal box after running a whole procedure of automatic Feeding pre- printed die-cutting paper (paper stock frame), Folding the paper (by mechanical device), hot press molding (adhesive box four corners), automatic box counting collection, microcomputer controlling. Suitable for the production of single-cell disposable paper boxes, paper lunch boxes, food packaging boxes.

Advanced & Advantage

Mechanical transmission、High speed、Energy saving、Stable Performance、Easy operation、microcomputer monitor、advanced and technological product.

* Stable speed 80 box/minute (machine can run more fast for some time, but not good for long time working, so we limit the machine max speed 80)

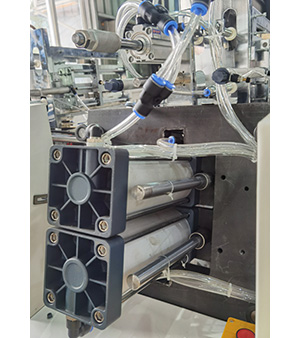

* Mechanical transmission, good quality main motor

* PLC Program control, easy operate, and intelligent

* 5 sensors detect all steps, fault guide, keep quality boxes and long life

* Quality mold, Using Aviation aluminium alloy material, high precision, light weight, Energy saving

* Quality electric elements, long life, (WVT, Schneider, AUTONICS, AirTAC famous brand)

* Working power only 3KW, save cost (not include the air compressor power)

Quality Electronic

|

|

|

Cylinder | Forming mold, up mold and bottom mold | Switches |

| ||

|

|

|

Paper stock frame | Collection Sensor | Collection system |

| ||

| ||

Main Circuit board | ||

1, Touch screen | 2, Temp controller | 3, Temp controller |

Operate the machine | Control up mold temp | Control down mold temp |

5, Temp controller switch | 6, Temp controller switch | 6, Power switch |

On & Off the temp | On & Off the temp |

|

Technical Specification

| Type | BC-700 |

Production | 70-80 times/min (The actual output is subject to the size of the product) |

Maximum | 650ml |

Suitable | 170-300g/m2 (one side PE Coated paper) white card paper,original paper, |

Total Power: | 3KW |

Total | 0.6T |

Overall | 1430 x 1600 x 1900 mm |

Working Air | Air pressure 0.4-0.5Mpa |

Gross weight | 700 KG (Wooden box packing weight) |

Grouped | Need to buy air compressor |

Working | 0.3-0.4 m³/min |

Components Brand

Motor | Main motor | WVT (CHINA) |

Electrical equipment | PLC | INOVANCE(China) |

Converter | INOVANCE(China) | |

Photoelectric | AUTONICS(Korea) | |

Contactor | Schneider(France) | |

Breaker | Schneider(France) | |

Start switch | AUTONICS (KOREA) | |

Tem table | AUTONICS (KOREA) | |

Pneumatic | Main cylinder | AirTAC (TAIWAN) |

Pneumatic components | FAMOUS BRAND (CHINA) | |

Bearings | HBR (CHINA) |

Quotation

NO. | DESCRIPTION | QUANTITY | FOB NINGBO PRICE | |

1 | BC-700 Automatic Paper Lunch Box Molding Machine | 1(set) | ¥85,000 RMB | |

2 | Extra mold | 1(piece) | ¥3,500 RMB | |

Payment term | 30% deposit, 70% before shipment | |||

Port | FOB Ningbo or Shanghai port | |||

Delivery time | 20 working days in general, 40 working days for customized machine | |||

Other | Buyer bears the cost during the installation & training | |||

Container loading | 20 Feet container load 5sets BC-700 | |||

After Sales Service

| 1 | Warranty: We offer 12 months warranty. During the warranty period, we provide free replacement of |

2 | Spare Parts: Each machine has its standard spare parts. |

3 | Manual, Video, to help operate machine, Questions response within 48 hours (except holiday). |

4 | FREE: The buyer come to learn how to operate machine, how to adjust, how to change parts. It is free. |

5 | The seller agrees to dispatch technician for installation & training, the cost covered by the buyer. |

6 | Mechanic overseas Cost include: |

S. If different width, we can do it according to your requirement.