- Mobile:

- +86 13625872111

- Tel:

- 0577-59886565

- Email:

- admin@bcmachinery.cn

- Add:

- #358 Weier Road Nanbin Street Ruian City Zhejiang China

Sample Show

Brief Description

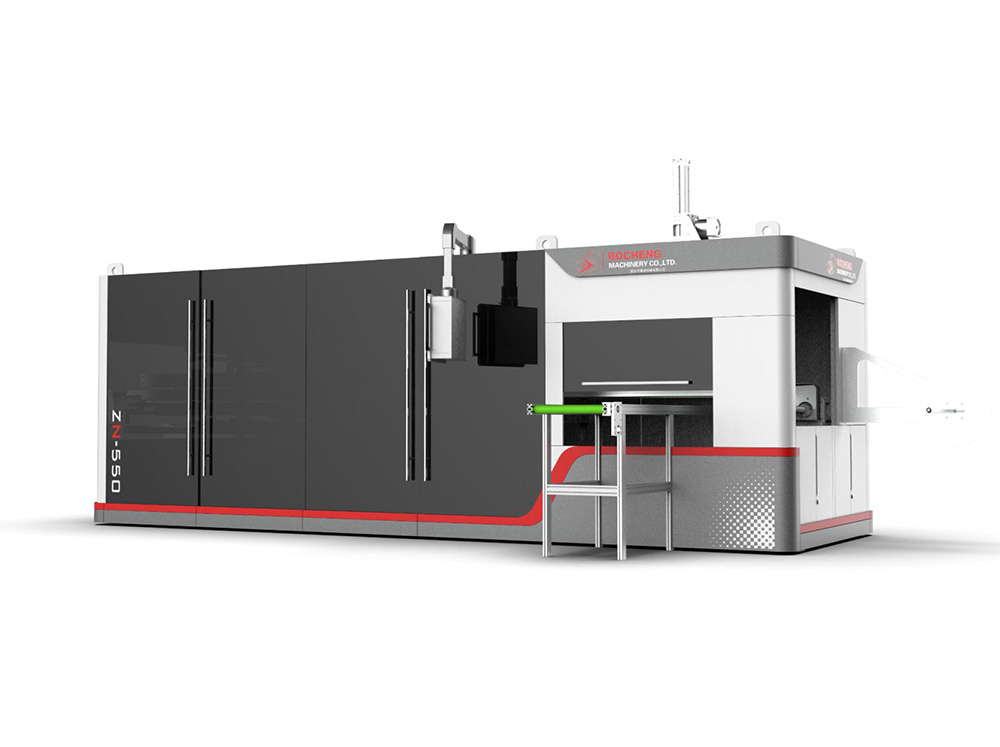

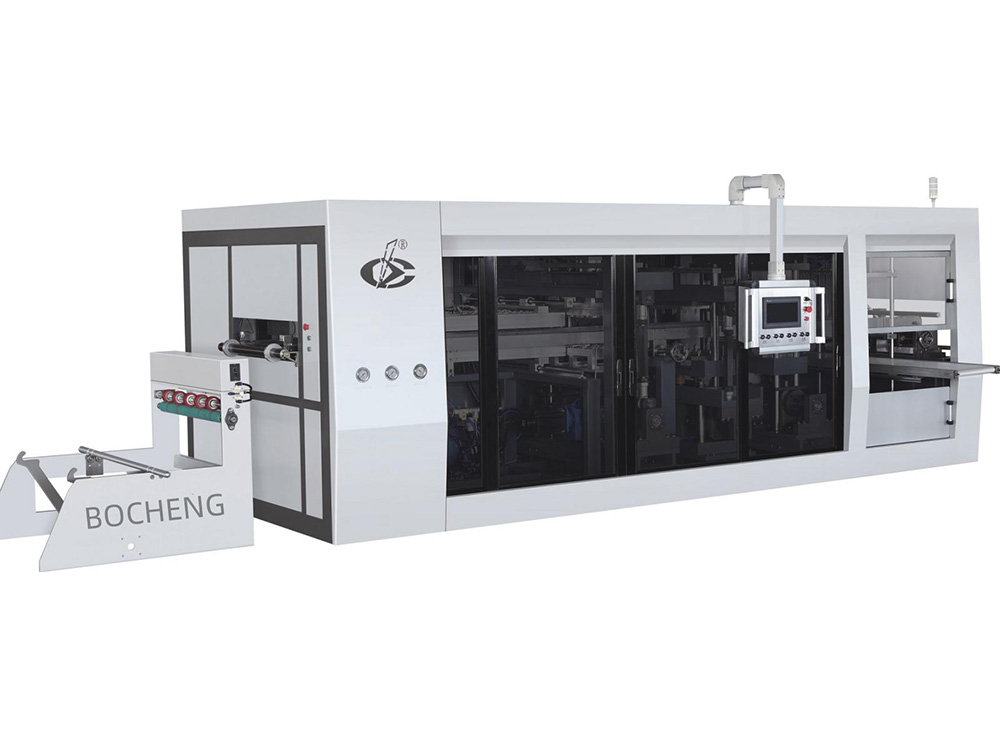

BC-EPB3 is our best selling Automatic meal box making machine.

With advanced design and intelligent program, more reliable and durable, cost effective.

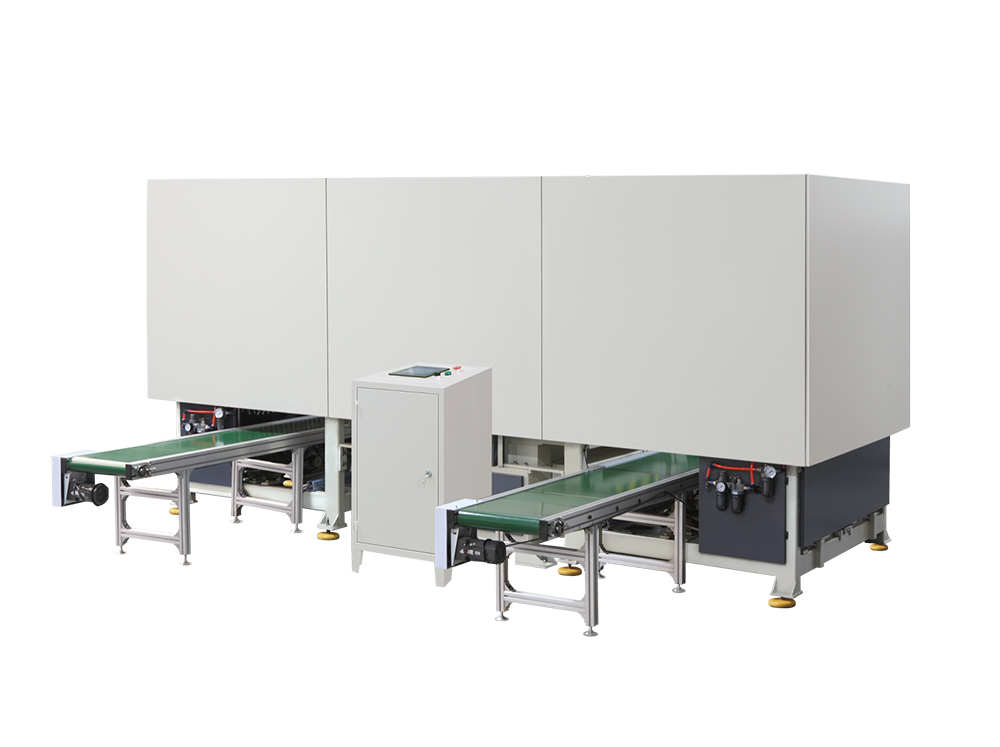

It makes both one-side or two-side PE-film-coated paper meal box after running a whole procedure of automatic Feeding Pre- printed die-cutting paper (paper stock frame), Pre heating box corners (hot air blower comes with heating pipe), Folding the paper (by mechanical device), hot press molding (adhesive box four corners), automatic box counting collection, microcomputer controlling. Suitable for the production of single-cell disposable paper boxes, paper lunch boxes, food packaging boxes.

Advanced & Advantage

Mechanical transmission、High speed、Energy saving、Stable Performance、Easy operation、microcomputer monitor、advanced and technological product.

Automatic paper molding equipment, has the advantages of high speed, convenient operation etc.This machine adopts built-in hot air generator, suitable for single PE coated paper.

For the production of single-cell disposable paper boxes, paper boxes, cupcakes, food packaging boxes and FBJ-C automatic intelligent medium speed cake cup machine through the automatic feed paper, heating (comes with hot air generating device), hot press molding (adhesive box four corners), automatic points collected, microcomputer control of continuous processes.

* Stable speed 45box/minute (machine can run more fast for some time, but not good for long time working, so we limit the machine max speed 45)

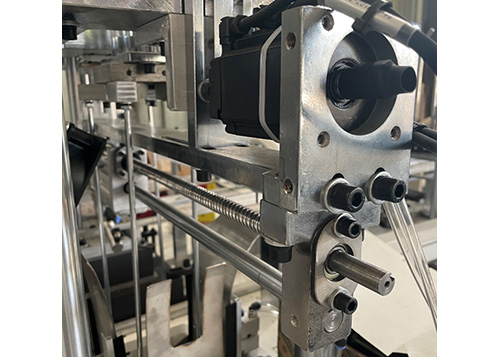

* Mechanical transmission, good quality main motor

* PLC Program control, easy operate, and intelligent

* Quality mold, Using Aviation aluminium alloy material, high precision, light weight, Energy saving

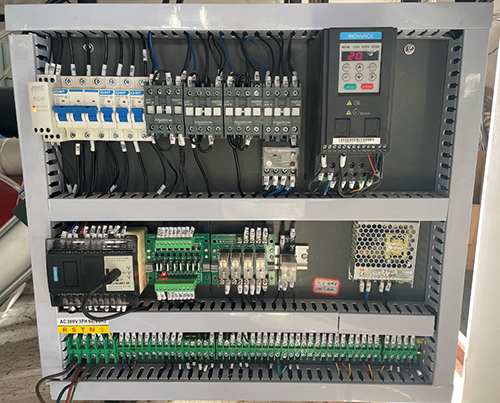

* Quality electric elements, long life, (WVT, Schneider, AUTONICS, AirTAC famous brand)

* Working power only 5KW, save cost (not include the air compressor power)

Quality Electronic

|

|

| |||||

PLC | LED Touch screen | Transducer | |||||

| |||||||

|

|

| |||||

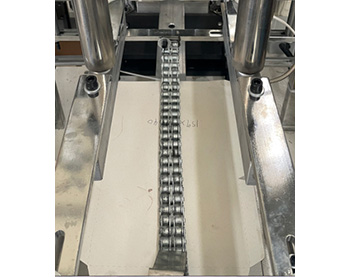

Paper stock frame | Mechanical transmission | Frequency converter | |||||

| |||||||

|

|

|

|

| |||

Sensor 1 | Sensor 2 | Sensor 3 | Sensor 4 | Sensor 5 | |||

Monitor the paper quantity level | Monitor main cylinder | Monitor paper moving | Monitor box collection | Monitor sivo collection system | |||

| |||||||

|

| ||||||

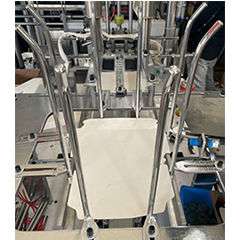

Forming mold, up mold and bottom mold | SIVO Motor | ||||||

|

| ||||||

|

|

| |||||

Two heaters | Paper conveying | Main cylinder | |||||

1, Paper Suck Switch | 2, Touch screen | 7, Power switch | 8, On switch | 9, Off switch |

Turn on, to suck and feed paper | Operate the machine | Control machine total power | Start machine | Off work machine |

3, Temp controller | 4, Temp controller | 5, Temp controller switch | 6, Temp controller switch | 10, Urgent stop |

Control pre heating | Control mold temp | On & Off the temp | On & Off the temp |

|

Circuit board

Technical Specification

| Type | BC-EPB3 |

Production capacity | 30-45 times/min (The actual output is subject to the size of the product) |

Maximum size: | 480 x 480mm |

Suitable Material: | 200-400g/m2 (one side or two side PE Coated paper) |

Total Power: | 5KW |

Total Weight: | 0.7T |

Overall Dimension: | 1550 x 1350 x 1800 mm |

Working Air Source: | Air pressure 0.4-0.5Mpa (Need to buy compressor) |

Gross weight | 800 KG (Wooden box packing weight) |

Grouped equipment | Need to buy air compressor |

Working volume | 0.3-0.4 m³/min |

Components Brand

Motor | Main motor | WVT (CHINA) |

Electrical equipment | PLC | LS (KOREA) |

Frequency converter | LS (KOREA) | |

Photoelectric switch | AUTONICS (KOREA) | |

Contactor | SCHNEIDER | |

Breaker | SCHNEIDER | |

Start switch | AUTONICS (KOREA) | |

Temperature control | FAMOUS BRAND (CHINA) | |

Pneumatic | Main cylinder | AirTAC (TAIWAN) |

Other pneumatic components | FAMOUS BRAND (CHINA) | |

other bearings | HBR (CHINA) |

Quotation

NO. | DESCRIPTION | QUANTITY | FOB NINGBO PRICE | |

1 | BC-EPB3 Automatic Intelligence Paper Box | 1(set) | $10,000USD | |

2 | Extra mold | 1(piece) | $700USD | |

Payment term | 30% deposit, 70% before shipment | |||

Port | FOB Ningbo or Shanghai port | |||

Delivery time | 20 working days in general, 40 working days for customized machine | |||

Other | Buyer bears the cost during the installation & training (buyer should pay | |||

Container loading | 20 Feet container load 4sets BC-EPB3 | |||

After Sales Service

| 1 | Warranty: We offer 12 months warranty. During the warranty period, we provide free replacement |

2 | Spare Parts: Each machine has its standard spare parts. |

3 | Manual, Video, to help operate machine, Questions response within 48 hours (except holiday). |

4 | FREE: The buyer come to learn how to operate machine, how to adjust, how to change parts. It is free. |

5 | The seller agrees to dispatch technician for installation & training, the cost covered by the buyer. |

6 | Mechanic overseas Cost include: |

S. If different width, we can do it according to your requirement.